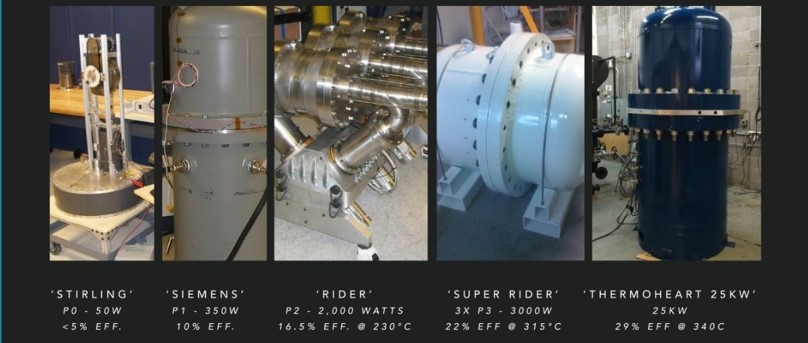

Cool Energy, Inc launched in 2006 with a vision to generate economical electricity from medium-temperature (100 to 400 C) thermal energy from industrial processes, solar, and geothermal sources. Five generations of Stirling engine have been designed, modeled, prototyped, and tested with output powers growing from 50 Watts to 25,000 Watts and efficiencies climbing from 5% to 30%. Stirling heat pumping has also been demonstrated with these units, which have been delivered to customers in the US, France, Italy, and China for pilot demonstrations.

Over this timeline, Cool Energy has been awarded 12 US patents, two of which cover the unique single-acting rotary design of the 25 kW ThermoHeart Engine. Cool Energy has been awarded and executed competitive development grants from the Department of Energy (DOE - geothermal), National Science Foundation (NSF - solar) and Environmental Protection Agency (EPA - industrial heat recovery).

The ThermoHeart® Engine, based on a single-acting alpha Stirling cycle architecture, incorporates modern design techniques such as gradient-descent performance optimization in design, self-lubricating seals, and high-surface-area, high-effectiveness heat exchangers. It is designed to be quiet, low-maintenance (20,000 hour service interval), and highly efficient, achieving nearly 30% conversion efficiency in demonstration testing.

The ThermoHeart 25 kW modules can be connected together on heat manifolds in parallel or series configurations to be used with thermal energy flows that can produce outputs higher than 25 kW. These units also operate with high coefficient-of-performance (COP) when used as heat pumps.

Cool Energy drew back from manufacturing operations due to COVID-era disruptions, and has executed consulting contracts and pursued licensing arrangements with dozens of clients and collaborators since entering a fabrication-free model in 2020.

For inquiries about Stirling cycle consulting services, design licensing for specific applications, project investment, or collaborative design/deployment projects, please contact us at info@coolenergy.com or via call/text to (303) 416-6130.

We are eager to hear how our expertise and designs for Stirling cycle machines can be useful in your energy management and power generation projects!.